Our Products

Home > Our Products > STP

Sewage Treatment Plants

Waste Water Reclamation

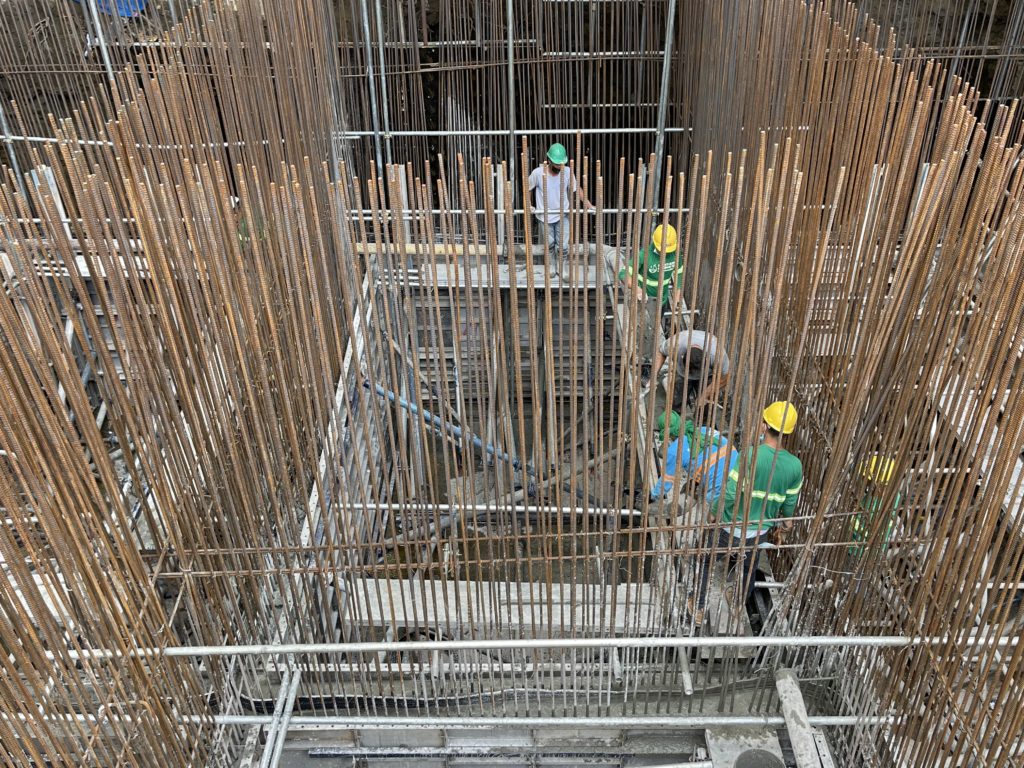

DESIGN AND BUILD SOLUTIONS FROM THE GROUND UP

Sequential Batch Rector

| Model NBWS SBR | Capacity | # Chambers BOD 250 | Blower HP Rating | # Chambers BOD 500 | # Chambers BOD 250 | # Chambers BOD 800 | # Chambers BOD 250 |

|---|---|---|---|---|---|---|---|

| SEQUENTIAL BATCH REACTOR | |||||||

| 250 BOD | 500 BOD | 800 BOD | |||||

| NBWS-STP-SBR-20 | 20 | 1 | 5 | 1 | 5 | 1 | 7.5 |

| NBWS-STP-SBR-30 | 30 | 1 | 5 | 1 | 5 | 1 | 7.5 |

| NBWS-STP-SBR-50 | 50 | 1 | 5 | 1 | 7.5 | 1 | 10 |

| NBWS-STP-SBR-75 | 75 | 1 | 5 | 2 | 7.5 | 2 | 10 |

| NBWS-STP-SBR-100 | 100 | 1 | 7.5 | 2 | 7.5 | 2 | 10 |

| NBWS-STP-SBR-150 | 150 | 2 | 7.5 | 2 | 10 | 2 | 15 |

| NBWS-STP-SBR-200 | 200 | 2 | 10 | 2 | 15 | 2 | 20 |

| NBWS-STP-SBR-300 | 300 | 2 | 15 | 2 | 15 | 2 | 40 |

| NBWS-STP-SBR-400 | 400 | 2 | 20 | 2 | 20 | 2 | 40 |

| NBWS-STP-SBR-500 | 500 | 2 | 25 | 2 | 40 | 2 | 50 |

| NBWS-STP-SBR-750 | 750 | 3 | 25 | 3 | 40 | 2 | 60 |

| NBWS-STP-SBR-1000 | 1000 | 3 | 25 | 3 | 40 | 3 | 60 |

| NBWS-STP-SBR-1500 | 1500 | 3 | 40 | 3 | 60 | 3 | 50 |

| NBWS-STP-SBR-2000 | 2000 | 3 | 40 | 3 | 60 | 3 | 60 |

| NBWS-STP-SBR-2500 | 2500 | 3 | 50 | 4 | 60 | 4 | 70 |

| Note: Blower rating is based on 4500 mmAq | |||||||

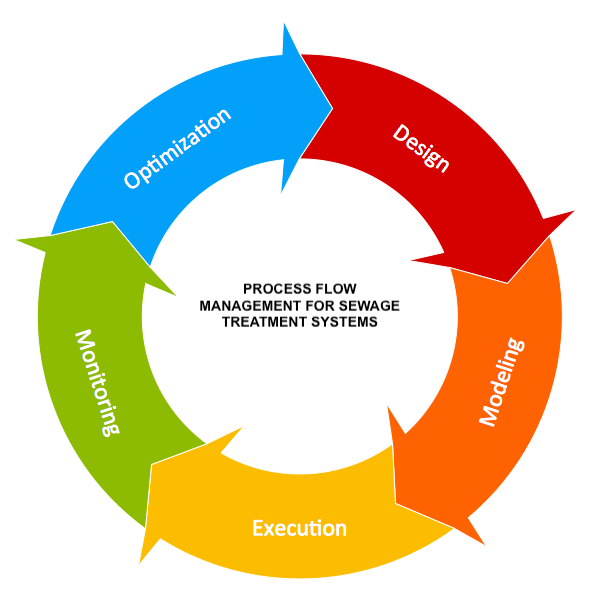

There are different options on processing commercial and industrial waste-water and municipal sewage water. Conventional systems require large capital expenditures and large power consumption.

Our SBR, MBR, and MBBR systems offer solutions that require lower footprint and power requirements.

The sequencing batch reactor (SBR) is a fill-anddraw activated sludge system for wastewater treatment. In this system, wastewater is added to a single “batch” reactor, treated to remove undesirable components, and then discharged. Equalization, aeration, and clarification can all be achieved using a single batch reactor. To optimize the performance of the system, two or more batch reactors are used in a predetermined sequence of operations. SBR systems have been successfully used to treat both municipal and industrial wastewater. They are uniquely suited for wastewater treatment applications characterized by low or intermittent flow conditions.

Membrane Bio Reactor

| Model NBWS MBR | Capacity | # of MBR Modules | # of Containers | Power Consumption (kW) | |||

|---|---|---|---|---|---|---|---|

| MEMBRANE BIO REACTOR | |||||||

| NBWS-STP-MBR-50 | 50 | 1 | 1 x 20' | 20 | |||

| NBWS-STP-SBR-100 | 50 | 1 | 1 x 40' | 30 | |||

| NBWS-STP-SBR-150 | 75 | 2 | 2 x 40' | 40 | |||

| NBWS-STP-SBR-200 | 100 | 2 | 2 x 40' | 55 | |||

| NBWS-STP-SBR-300 | 150 | 2 | 3 x 40' | 85 | |||

| NBWS-STP-SBR-400 | 200 | 4 | 4 x 40' | 110 | |||

| NBWS-STP-SBR-500 | 300 | 4 | 5 x 40' | 140 | |||

| PARAMETERS | INFLUENT QUALITY | EFFLUENT QUALITY | |||||

| BOD | 150 - 500 | < 10 | |||||

| TSS | 150 - 400 | < 10 | |||||

| pH | 6.5 - 8.5 | 6.5 - 8.5 | |||||

| NITRATES | < 100 | < 30 | |||||

| PHOSPHATES | < 30 | < 10 | |||||

| BACTERIA | PRESENT | ND | |||||

| CHLORINE | ND | 0.5 - 2.0 | |||||

| MBR Average lifespan of MBR Module 3 - 7 years. Effluent quality is based on projections using MBR. SBR Effluent quality will be based on tertiary treatment options. | |||||||

Membrane Bioreactor (MBR) is a process that utilizes a membrane ultra filtration process and activated sludge process. The MBR process is used in place of the secondary sedimentation tank and sand filter used for tertiary treatment in the conventional activated sludge process. This systems requires a smaller footprint compared to conventional systems; while maintaining a higher effluent quality.